JD-S4A Pet Semi-Automatic Bottle Blowing Machine

Ketwords:

JD-S4A Pet Semi-Automatic Bottle Blowing Machine

Classification:

- Details

-

JD-S3A, JD-S4A Two step fully auto-loader bottle blowing machine is improved on bases of JD-S3, JD-S4 bottle blowing machine. It is the most advanced and highly developed technology two-step fully auto-loader bottle blowing machine in the world. The machines have won a number of invention patents.

JD-S3A, JD-S4A Two step fully auto-loader bottle blowing machine is improved on bases of JD-S3, JD-S4 bottle blowing machine. It is the most advanced and highly developed technology two-step fully auto-loader bottle blowing machine in the world. The machines have won a number of invention patents.JD-S4A two step bottle blowing machine has four cylinders. The capacity can reach 2200-2400B/H for 500ml bottle. Far-infrared auto-loader rotary heater now is improved on the basis of JD-S4 model manually putting perform, we only need to put all the performs into the loader, dispatch the perform into the heater through the upper-loader, go one round to the exit after heating, and take the performs to the closed mould by hand for blowing, and the blew bottles will come out automatically. It specialized in the production of blowing the plastic container (PET/PMMA/PS), it has small size, low energy consumption rate, high efficiency, low investment, easy to operate and maintain.

S/N Item Unit JD-S4A 1 Raw material PET/PMMA/PS/PP 2 orking pressure(air) Mpa 0.7-0.9 3 Blowing-pressure Mpa 0.9-3.0 4 Voltage/Frequency V/Hz 220V/380V/50Hz、60Hz 5 Rated power Heater kW 10.5(220) Air Compressor 15(380V) 6 Max mould effective dimension(L*W*H) mm 360*535*220 7 Mould Opening Stroke mm 210 8 Max mould thickness mm 220 9 Center Distance Between two Cavities mm 150 10 Volume of product ml 10-2000 11 Max Stretch Length mm 360 12 Ckanping force kN 50 13 Capacity pcs/h 2200-2400B/H 14 Machine dimension

(L*W*H)Main machine mm 1330*780*2000 Heater 1850*1300*1850 15 Machine weight Main machine kg 600 Heater 500 16 Air Compressor Dimension(L*W*H) mm 1700*670*1220 weight kg 410 17 Air Compressor Dimension(L*W*H) mm 250*250*600 weight > kg 30 18 Freezed Dryer Dimension(L*W*H) mm 890*550*1000 weight kg 175 19 Temperature range ℃ 60-110(PET)

150-180(PMMA、PS、PP)

More Products

Bottle blowing machine

PET semi-auto blow molding machine

-

JD-S4 Pet Semi-Automatic Bottle Blowing Machine

JD-S3, JD-S4 Two step semi automatic bottle blowing machine is improved on bases of JD-88-A bottle blowing machine .It is the most advanced semi automatic bottle blowing machine in the word . The machine has a number of patent applications.

-

JD-S4A Pet Semi-Automatic Bottle Blowing Machine

JD-S3A, JD-S4A Two step fully auto-loader bottle blowing machine is improved on bases of JD-S3, JD-S4 bottle blowing machine. It is the most advanced and highly developed technology two-step fully auto-loader bottle blowing machine in the world. The machines have won a number of invention patents. JD-S4A two step bottle blowing machine has four cylinders. The capacity can reach 2200-2400B/H for 500ml bottle. Far-infrared auto-loader rotary heater now is improved on the basis of JD-S4 model manually putting perform, we only need to put all the performs into the loader, dispatch the perform into the heater through the upper-loader, go one round to the exit after heating, and take the performs to the closed mould by hand for blowing, and the blew bottles will come out automatically. It specialized in the production of blowing the plastic container (PET/PMMA/PS), it has small size, low energy consumption rate, high efficiency, low investment, easy to operate and maintain.

-

JD-88-A Pet Semi-Automatic Bottle Blowing Machine

JD-88-A two step semi Automatic Computer Controlled Rotatory Infrared Oven Heating Bottle blowing Machine specializes in the production of blowing the plastic container (PET/PMMA/PS/PP) within 2L which is heat –resistant and superior difficulty.

-

JD-88-B Pet Semi-Automatic Bottle Blowing Machine

JD-88-B series semi automatic bottle blowing machine from 2liter to 10liter,one cavity, used for blowing the cosmatic ,sannitizer ,hand washing liquid bottles . It has advantages of low cost, small size and high efficiency.

-

JD-88-C Pet Semi-Automatic Bottle Blowing Machine

JD-88-C two step semi-Automatic Computer Controlled Rotatory Infrared Oven Heating Bottle blowing Machine is suitable to produce different shaped bottles such as three gallon, five gallon and Ø100- Ø200 mm wide neck bottles with PET/PMMA/PS.

-

JD-88-C1 Pmma Semi-Automatic Bottle Blowing Machine

JD-88-C two steps semi-automatic 5 gallon bottle blowing machine, including oneblower, one rotary heater : specialized in blowing big neck φ650mm lamp mould, thecapacity can reach 40B/H.

-

JD-88-BEX Pet Semi-Automatic Bottle Blowing Machine

Our company specialized in making the different specification of PET material fully automatic bottle blowing machine and semi automatic bottle machine , the bottle mold and the bottle products , all is the important products of the corona virus issue .

-

JD-88-A1 Pet Semi-Automatic Bottle Blowing Machine

JD-88-A1 two step hest-resistant (90℃) semi-automatic bottle blowing machine is used to produce containers which the material is PET, PMMA, PS.

PET automatic blow molding machine

-

KDB-D4 Pet Fully Automatic Bottle Blowing Machine

KD A series fully automatic bottle blowing machine from 0.2liter to 2 liter , from 2 cavity to 6 cavity , used for blowing the cosmatic ,sannitizer ,hand washing liquid bottles , this machine is blowing from upside .

-

KDB-D2 Pet Fully Automatic Bottle Blowing Machine

Semi-automatic bottle blowing machine includes JD-88,JD-88A,JD-88-B,JD-88-C,applies to produce PET bottles such as water bottle,beverage bottle,oil bottles,insecticide bottles,PC bottles,PP bottles,PE bottles etc.

-

KDB-D4-PP Fully Automatic Bottle Blowing Machine

Semi-automatic bottle blowing machine includes JD-88,JD-88A,JD-88-B,JD-88-C,applies to produce PET bottles such as water bottle,beverage bottle,oil bottles,insecticide bottles,PC bottles,PP bottles,PE bottles etc.Hot resistant container.

PP PE one-step blow molding machine

-

JKD-8 PP/PE One Step Fully Automatic Blow Moudling Machine

TKD-8 series parallel move one step PP,PE full automatic blow moulding machine.Specialized in blowing PP, PE material sanitizer, cloth washing liquid, hand washing and milk bottles.

-

JKD-88 PP/PE One Step Fully Automatic Blow Moulding Machine

JKD-88 series storing tank PP,PE automatic hydraulic pressure bottle blowing machine. Specialized in blowing PP、PE material the big and medium water bucket,chemical bucket and oil bucket etc.

Injection machine

-

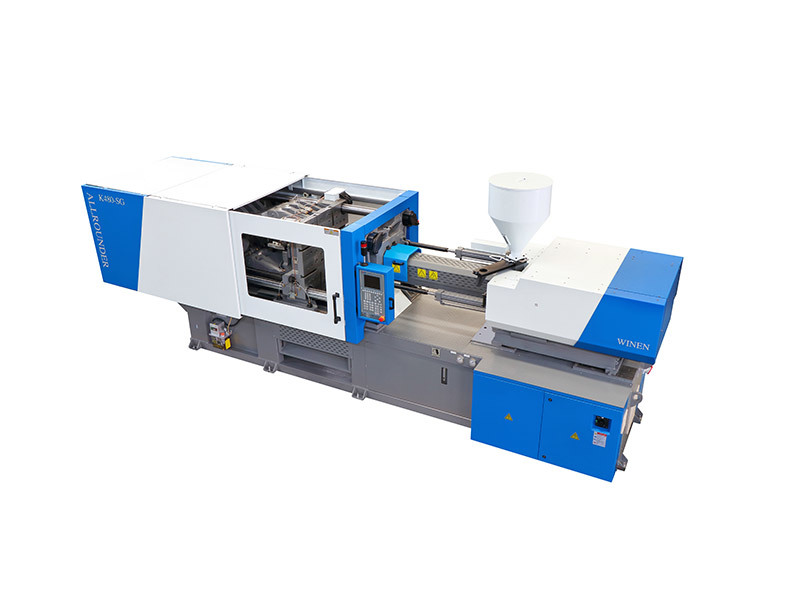

Injection molding machine

KD series plastic injection molding machine specialized in making 20mm,24mm,28mm neck preform & cap of cosmetic ,sanitizer and hand washing PET bottles. It can inject mineral water preforms,beverage bottle preforms, big neck preforms and five gallon bottle preforms.

-

Injection molding machine

KD series plastic injection molding machine specialized in making 20mm,24mm,28mm neck preform & cap of cosmetic ,sanitizer and hand washing PET bottles. It can inject mineral water preforms,beverage bottle preforms, big neck preforms and five gallon bottle preforms.

-

Injection molding machine

KD series plastic injection molding machine specialized in making 20mm, 24mn, 28mm neck preform& cap of cosmetic ,sanitizer and hand washing PET bottles. It can inject mineral water preforms,beverage bottle preforms, big neck preforms and five gallon bottle preforms.

-

Injection molding machine

KD series plastic injection molding machine specialized in making 20mm,24mm,28mm neck preform & cap of cosmetic ,sanitizer and hand washing PET bottles. It can inject mineral water preforms,beverage bottle preforms, big neck preforms and five gallon bottle preforms.

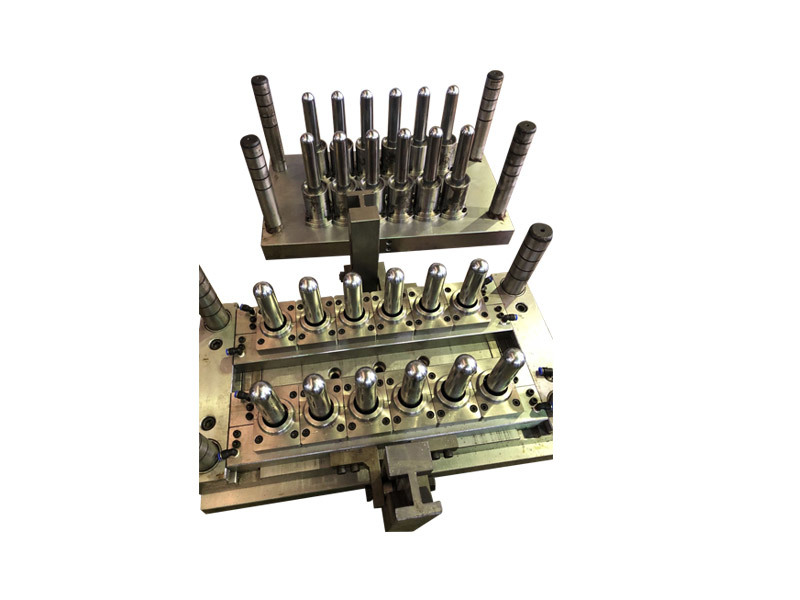

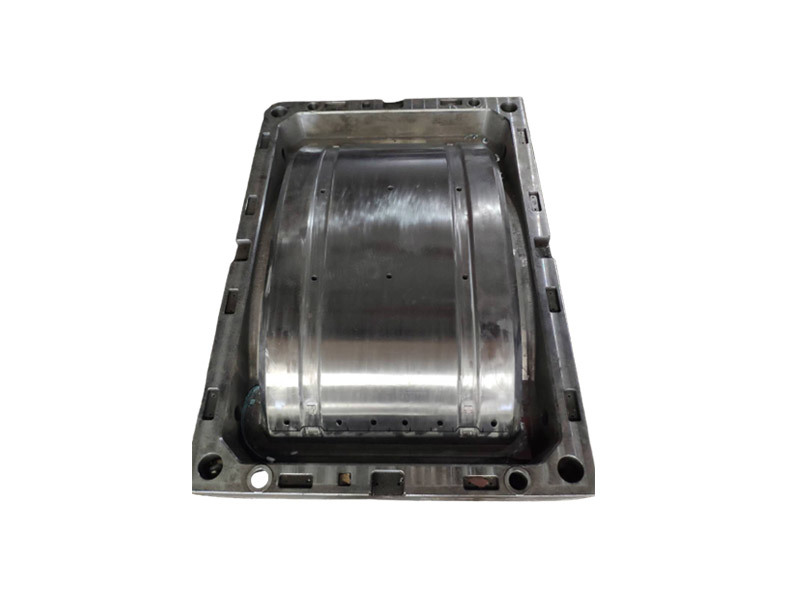

Mould

Preform mould, cap mould, bottle mould

-

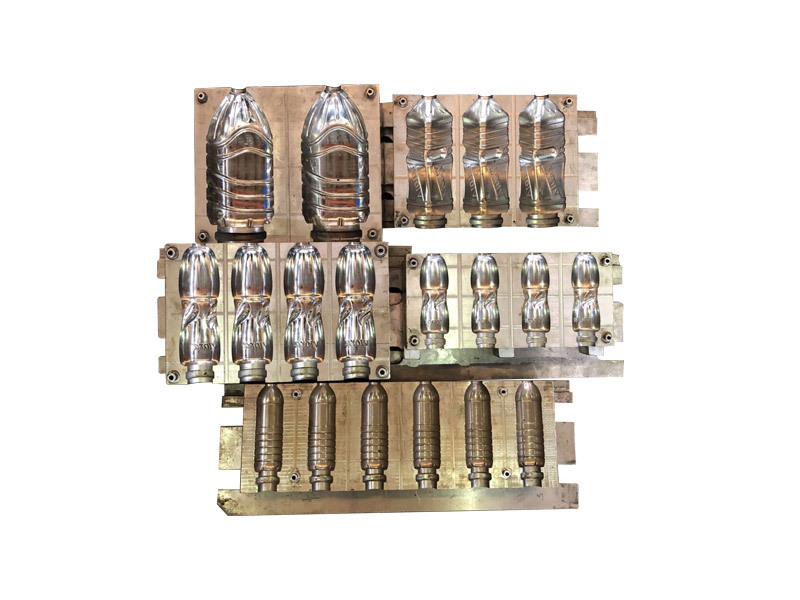

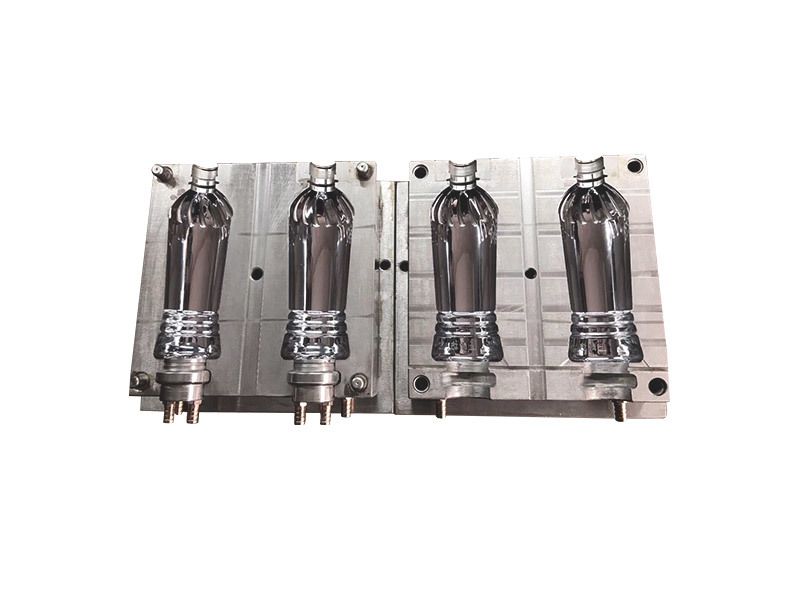

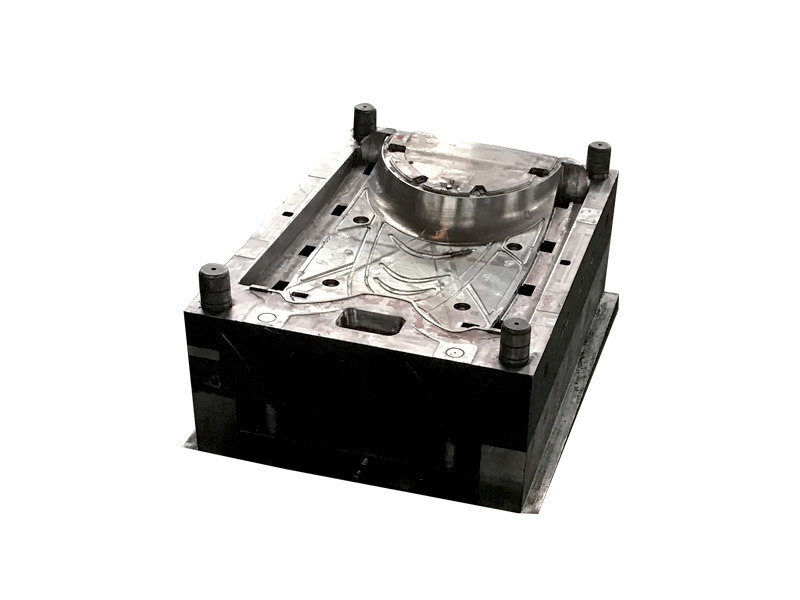

bottle mold

Bottle molds are tools used to make bottles, mainly for manufacturing bottles made of plastic or glass. Bottle molds occupy an important position in the field of mold manufacturing and are widely used in the plastic packaging industry, which is important for the production of high quality and efficient plastic bottles.

-

bottle mold

Bottle molds are tools used to make bottle-shaped products, which can precisely control the shape, size and surface quality of bottles. The mold manufacturing process needs to take into account the characteristics of the material, the molding process and the product design requirements.

-

bottle mold

The manufacturing of bottle molds involves a number of links, including mold design, material selection, processing and manufacturing, debugging and inspection.

-

bottle mold

Bottle molds are widely used in many fields such as automotive, electronics, home appliances, packaging, etc., especially important in the plastic packaging industry. High quality and high efficiency plastic bottle production can not be separated from the bottle mold support.

-

bottle mold

Bottle molds are tools used to make bottle-shaped products, which can precisely control the shape, size and surface quality of bottles. The mold manufacturing process needs to take into account the characteristics of the material, the molding process and the product design requirements.

-

bottle mold

Bottle molds occupy an important position in the field of mold manufacturing and are widely used in the plastic packaging industry, which is important for the production of high quality and efficient plastic bottles.

-

bottle mold

The manufacturing process requires the use of a variety of advanced machining equipment and processes, such as CNC machine tools, EDM, CNC milling and so on.

-

bottle mold

Bottle molds are tools used to make bottle-shaped products, which can precisely control the shape, size and surface quality of bottles. The mold manufacturing process needs to take into account the characteristics of the material, the molding process and the product design requirements.

-

bottle mold

Among them, mold design is the core link, which needs to take into account the molding process of the product, the fluidity of the material and the service life of the mold and other factors.

-

bottle mold

Bottle molds are tools used to make bottle-shaped products, which can precisely control the shape, size and surface quality of bottles. The mold manufacturing process needs to take into account the characteristics of the material, the molding process and the product design requirements.

-

bottle mold

The manufacturing of bottle molds involves a number of links, including mold design, material selection, processing and manufacturing, debugging and inspection. Among them, mold design is the core link, which needs to take into account the molding process of the product

-

bottle mold

Among them, mold design is the core link, which needs to take into account the molding process of the product, the fluidity of the material and the service life of the mold and other factors.

-

bottle mold

Application areas:Bottle molds are widely used in many fields such as automotive, electronics, home appliances, packaging, etc., especially important in the plastic packaging industry.

-

bottle mold

The manufacturing of bottle molds involves a number of links, including mold design, material selection, processing and manufacturing, debugging and inspection.

-

bottle mold

Among them, mold design is the core link, which needs to take into account the molding process of the product, the fluidity of the material and the service life of the mold and other factors.

-

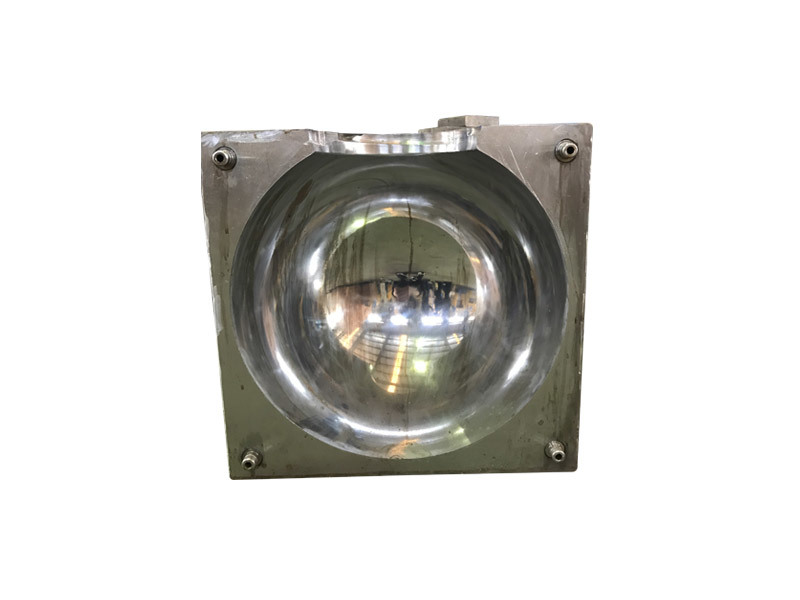

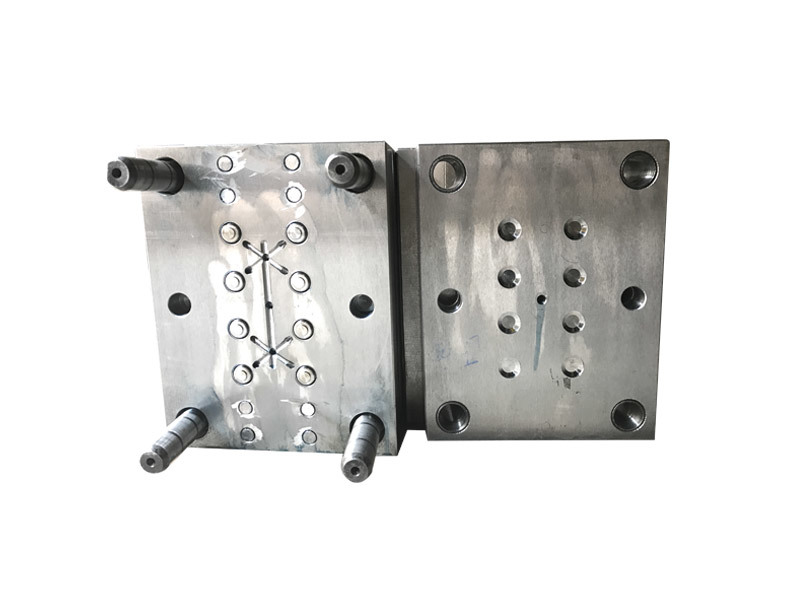

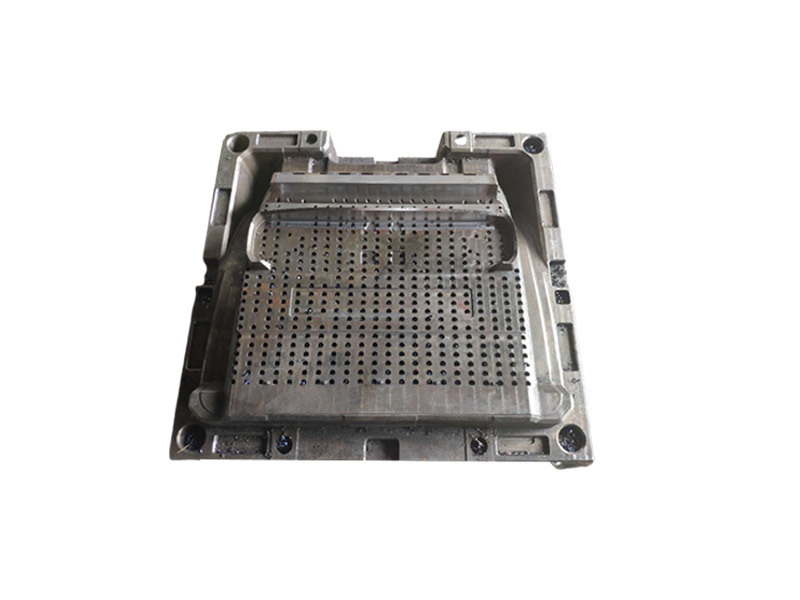

cap mold

A cap mold is a type of mold used to manufacture caps and usually consists of an upper mold assembly and a lower mold assembly. The lower mold assembly includes a template assembly, a core, a toothed die, an adjusting gear and an adjusting ring.

-

cap mold

Complex structure: the mold design is complex and includes several components and adjustment mechanisms to ensure the flexibility and accuracy of the mold.

-

cap mold

The template assembly is provided with adjustment holes, the core is set in the template assembly, the toothed mold is set on the core and meshes with the adjusting ring through the adjusting gear, and the angle between the toothed mold and the core can be adjusted by rotating the adjusting gear through the adjusting screws, which is simple to operate and requires short time.

-

cap mold

Complex structure: the mold design is complex and includes several components and adjustment mechanisms to ensure the flexibility and accuracy of the mold.Easy operation: the angle between the tooth mold and the core can be adjusted simply and quickly by adjusting screws, which improves the production efficiency.

-

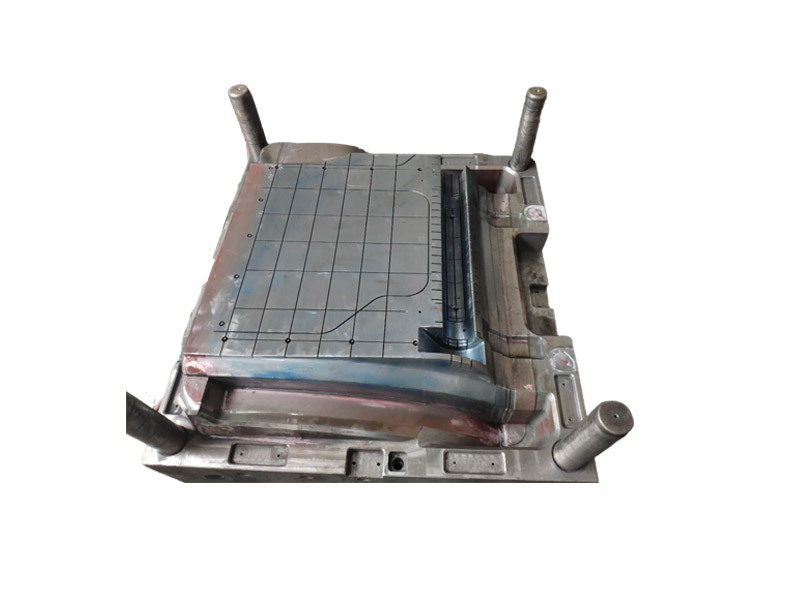

Preform mould

Precast mold is a kind of cement product mold used for producing precast parts, which is usually used in highway, high-speed railway roadside, road, highway, river, reservoir, dike, embankment, mountain and other places.

-

Preform mould

Precast moulds are usually made of high-quality steel, with high strength, wear-resistant, easy to take off the mold and other characteristics, and can accurately mold various specifications of foundation pier.

-

Preform mould

These molds need to have sufficient bearing capacity, rigidity and stability during the production process to ensure that they can reliably withstand weight and lateral pressure when pouring concrete.

-

Preform mould

According to the different scenes of use, precast mould is also known as high speed precast mould, high speed rail precast mould, road precast mould, highway precast mould, river precast mould, reservoir precast mould, river embankment precast mould, dyke precast mould, mountain precast mould and so on.

-

Preform mould

Precast molds are widely used in various infrastructure construction projects, such as highways, high-speed railroad curbs, roads, highways, rivers, reservoirs, dykes, embankments and mountains. The use of these molds improves construction efficiency, reduces the amount of on-site work, and ensures the quality and precision of the components.

-

bottle mold

Bottle molds are tools used to make bottle-shaped products, which can precisely control the shape, size and surface quality of bottles. The mold manufacturing process needs to take into account the characteristics of the material, the molding process and the product design requirements.

-

Big neck PET preform mould

According to the different scenes of use, precast mould is also known as high speed precast mould, high speed rail precast mould, road precast mould, highway precast mould, river precast mould, reservoir precast mould, river embankment precast mould, dyke precast mould, mountain precast mould and so on.

-

cap mold

The template assembly is provided with adjustment holes, the core is set in the template assembly, the toothed mold is set on the core and meshes with the adjusting ring through the adjusting gear, and the angle between the toothed mold and the core can be adjusted by rotating the adjusting gear through the adjusting screws, which is simple to operate and requires short time.

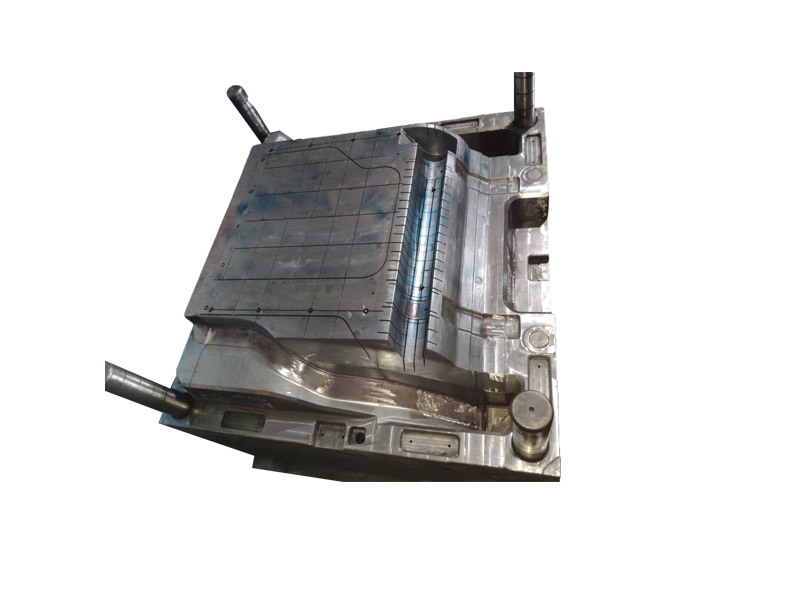

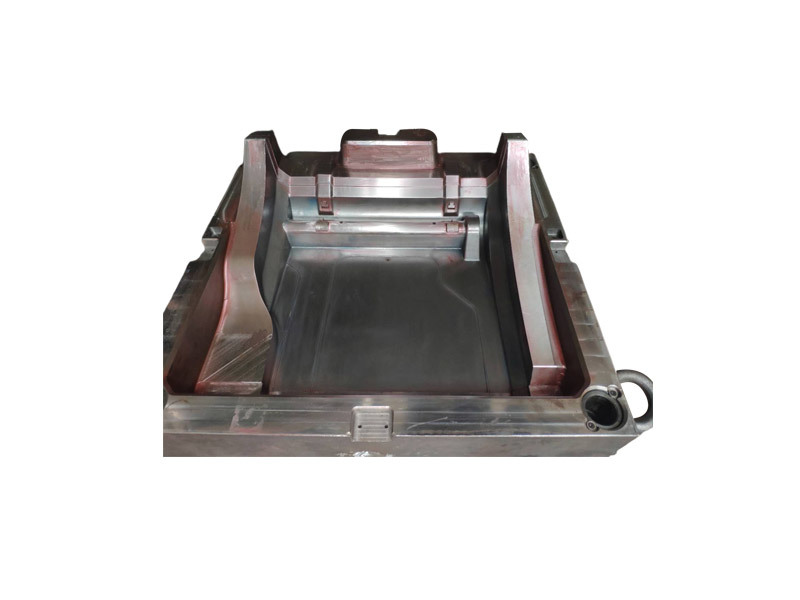

Auto parts mould

-

Auto parts mould

Auto parts molds are special tools used to manufacture various parts of automobiles, mainly including stamping molds, injection molds and die-casting molds and other types.

-

Auto parts mould

Stamping mold is one of the most commonly used types of molds in automobile manufacturing, which is mainly used for stamping metal sheets into the shape of various auto parts, such as body coverings, chassis parts, hoods, etc.

-

Auto parts mould

Injection molds are mainly used to produce plastic products such as automotive interior parts, exterior parts, and electrical parts. It forms the required plastic products by injecting molten plastic into the mold cavity and cooling and curing it.

-

Auto parts mould

Injection molds are usually composed of a fixed mold, a moving mold, a pouring system, a cooling system and other components, and the design needs to take into account factors such as the type of plastic, fluidity and shrinkage.

-

Auto parts mould

Auto parts molds are widely used in all aspects of automobile manufacturing, from the stamping of body covering parts to the injection molding of interior parts to the die-casting of engine blocks, each of which requires precise molds to ensure the quality and performance of the parts.

Commodity mould

-

Commodity Mould

Processing objects: hardware molds, plastic molds and special molds. Hardware molds are further subdivided into stamping molds, forging molds, extrusion molds, die-casting molds and so on.

-

Commodity Mould

Structure: single-piece molds and multi-piece molds, which are used to manufacture a single product and multiple identical products, respectively.

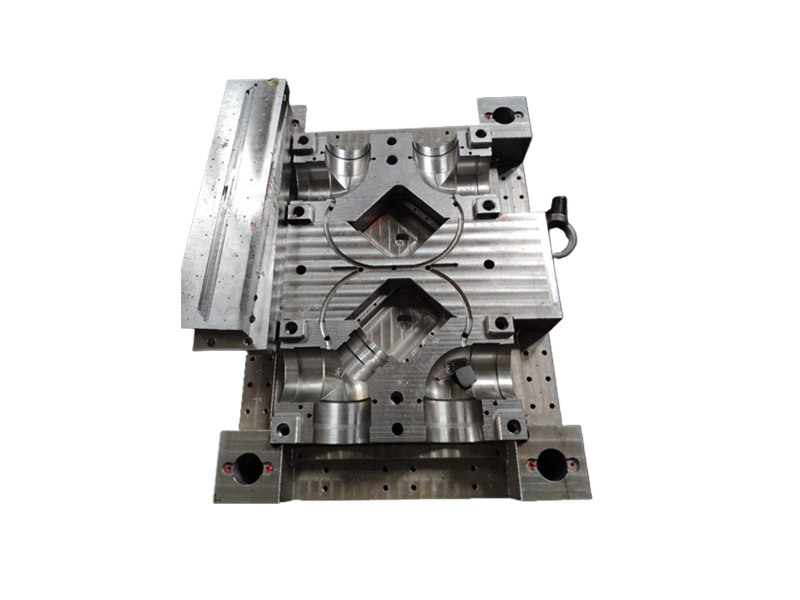

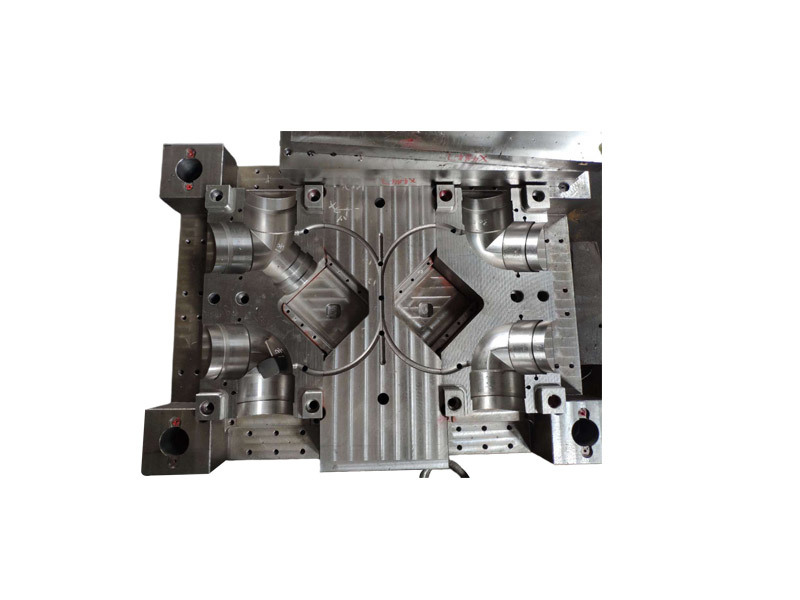

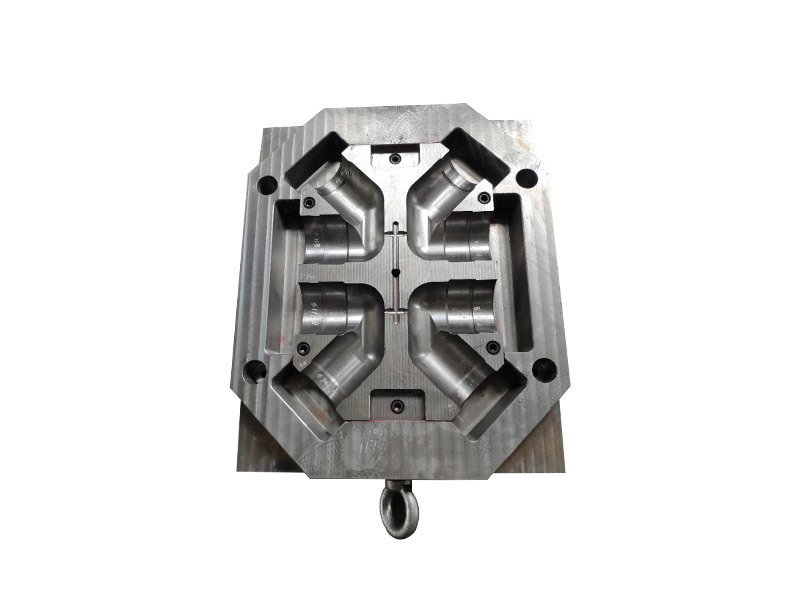

PVC pipe fitting mould

-

PVC Pipe fitting mould

PVC pipe fitting molds are widely used in the field of home building materials, such as drain pipes, water supply pipes, electric wire pipes and so on, because of their durability, low price and easy processing characteristics.

-

PVC Pipe fitting mould

The use of PVC molds can ensure the consistent size and shape of the pipes and improve the construction efficiency and safety. In addition, PVC molds have high productivity and durability in the production process, and are relatively easy to maintain, ensuring that the shape, size and surface quality of the products meet the predetermined standards.

-

PVC Pipe fitting mould

PVC pipe fitting molds are mainly used to produce PVC pipes and other PVC products, which are widely used in the fields of drainage, water supply, wire pipes, etc. PVC pipe fitting molds can be divided into various types, each type is suitable for different application scenarios.

-

PVC Pipe fitting mould

PVC pipe fitting mold usually consists of lower mold seat, upper mold seat, lower template, upper template, mold core and so on. The lower and upper mold holders are fixedly connected by support boards, and a high impact PVC pipe fitting mold core is set between the lower and upper templates.

-

PVC Pipe fitting mould

The upper mold base and upper template are equipped with pouring nozzles and sockets, and the sockets are movably inserted with mold release tilt rods to improve the convenience of mold release.

-

Tee fittings

The upper mold base and upper template are equipped with pouring nozzles and sockets, and the sockets are movably inserted with mold release tilt rods to improve the convenience of mold release.

Products

Caps

-

Lution pump

A cap mold is a type of mold used to manufacture caps and usually consists of an upper mold assembly and a lower mold assembly. The lower mold assembly includes a template assembly, a core, a toothed die, an adjusting gear and an adjusting ring.

-

Sports cap

The template assembly is provided with adjustment holes, the core is set in the template assembly, the toothed mold is set on the core and meshes with the adjusting ring through the adjusting gear, and the angle between the toothed mold and the core can be adjusted by rotating the adjusting gear through the adjusting screws, which is simple to operate and requires short time.

-

Cover

An injection head can be set in the cavities with back and forth movement, and an ejector seat can be ejected or retracted relative to the mold core, ensuring high product quality and production efficiency.

-

Cover

Semi-automatic bottle blowing machine includes JD-88,JD-88A,JD-88-B,JD-88-C,applies to produce PET bottles such as water bottle,beverage bottle,oil bottles,insecticide bottles,PC bottles,PP bottles,PE bottles etc.Hot resistant container.We also produce hotrunner preform mould,cap mould,bottle mould and thermosetting or thermoplastic big,middle,small plastic mould,good quality and reasonable price.our new design:KDS4,KD8 series automatic PET bottle blowing machine,Which capacity is from 2500-17000 bottles/hour according to the demand of customer,has been authorized to be "Zhejiang high-tech production".

-

Cover

The template assembly is provided with adjustment holes, the core is set in the template assembly, the toothed mold is set on the core and meshes with the adjusting ring through the adjusting gear, and the angle between the toothed mold and the core can be adjusted by rotating the adjusting gear through the adjusting screws, which is simple to operate and requires short time.

-

Cover

Easy operation: the angle between the tooth mold and the core can be adjusted simply and quickly by adjusting screws, which improves the production efficiency.Wide range of application: it is suitable for different types of cap products to meet diversified production requirements.

-

Cover

Complex structure: the mold design is complex and includes several components and adjustment mechanisms to ensure the flexibility and accuracy of the mold.

-

Gan Sprayer

Semi-automatic bottle blowing machine includes JD-88,JD-88A,JD-88-B,JD-88-C,applies to produce PET bottles such as water bottle,beverage bottle,oil bottles,insecticide bottles,PC bottles,PP bottles,PE bottles etc.Hot resistant container.We also produce hotrunner preform mould,cap mould,bottle mould and thermosetting or thermoplastic big,middle,small plastic mould,good quality and reasonable price.our new design:KDS4,KD8 series automatic PET bottle blowing machine,Which capacity is from 2500-17000 bottles/hour according to the demand of customer,has been authorized to be "Zhejiang high-tech production".

Preform

-

Preform

Semi-automatic bottle blowing machine includes JD-88,JD-88A,JD-88-B,JD-88-C,applies to produce PET bottles such as water bottle,beverage bottle,oil bottles,insecticide bottles,PC bottles,PP bottles,PE bottles etc.Hot resistant container.We also produce hotrunner preform mould,cap mould,bottle mould and thermosetting or thermoplastic big,middle,small plastic mould,good quality and reasonable price.our new design:KDS4,KD8 series automatic PET bottle blowing machine,Which capacity is from 2500-17000 bottles/hour according to the demand of customer,has been authorized to be "Zhejiang high-tech production".

-

Preform

Precast molds are widely used in various infrastructure construction projects, such as highways, high-speed railroad curbs, roads, highways, rivers, reservoirs, dykes, embankments and mountains. The use of these molds improves construction efficiency, reduces the amount of on-site work, and ensures the quality and precision of the components.

-

Preform

Precast moulds are usually made of high-quality steel, with high strength, wear-resistant, easy to take off the mold and other characteristics, and can accurately mold various specifications of foundation pier.

-

Preform

These molds need to have sufficient bearing capacity, rigidity and stability during the production process to ensure that they can reliably withstand weight and lateral pressure when pouring concrete.

-

Preform

These molds need to have sufficient bearing capacity, rigidity and stability during the production process to ensure that they can reliably withstand weight and lateral pressure when pouring concrete.

Leave A Message

Looking forward to your message, we will be happy to provide you with professional product solutions!

Want more product details? Send us an inquiry